At K&W Tool and Machine Inc., we specialize in manufacturing precision machined parts. With decades of knowledge and experience, our team is able to produce parts that require innovative tooling and fixturing in a timely manner. We approach each job with the intention of minimizing run-time by reducing the number of operations, therefore increasing accuracy and efficiency while decreasing cost. We are capable of holding tight tolerances in difficult to machine materials such as stainless steel, ballistic aluminum, titanium, specialty armor etc. CNC Machining uses a modern CAM system, state-of-the-art machining and CMM measuring equipment to ensure the highest quality product and customer satisfaction.

CNC Machining

- 3 – Takumi V11A Vertical Milling Machining Centers

- 20″ x 53″ working area

- X/Y/Z Travel – 43″ x 22″ x 25″

- 2 – SMTCL Vertical Milling Machine Centers VMC 850B

- 20″ x 30″ working area

- X/Y/Z Travel – 33″ x 22″ x 25″

- Takumi V15A Vertical Milling Center

- 27.5″ x 64″ working area

- X/Y/Z Travel – 57″ x 27″ x 27.5″

- SMTCL Vertical Milling Machine Centers VMC 1600B

- X/Y/Z Travel – 63″ x 32″ x 32″

- 4,500 lb maximum table weight

- VTEC Vertical Bridge Milling Center VB-3016

- 122″ x 51″ working area; 22,026 lb maximum table weight

- X/Y/Z Travel – 122″ x 63″ x 31″

- VTEC Vertical Bridge Milling Center VF-4000

- 204″ x 80″ working area; 28,600 lb maximum table weight

- X/Y/Z Travel – 165″ x 90″ x 36″

- SMTCL Vertical Gantry Milling Center EGC 2560

- X/Y/Z – 244″ x 106″ x 32″

- 40,000 lb maximum table weight

Manual Machining

- Bridgeport Series 1 – newal readouts & digital quill scale

- Devlieg Boring Mill – 30″ x 48″ table size

- Carlton Radial Drill – 8 ft arm – 19″ dia col

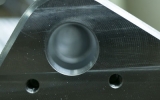

Photo Gallery

Click to enlarge.